Impossibly convenient. Incredibly delicious.

Your favorite specialty coffee drinks. Ready in seconds—with unrivaled flavor.

The Culmination of 700 Years of Coffee Craft & Science

-

The Best Beans, Period

The highest quality beans from roasters like Intelligentsia, Counter Culture, Equator and more.

-

The world’s most advanced brewing

Created by an MIT engineer to extract more flavor and aroma than previously possible.

-

Delivered to your kitchen hyper-fresh

Liquid nitrogen locks in the aroma—you’ll love tasting all the flavor notes.

-

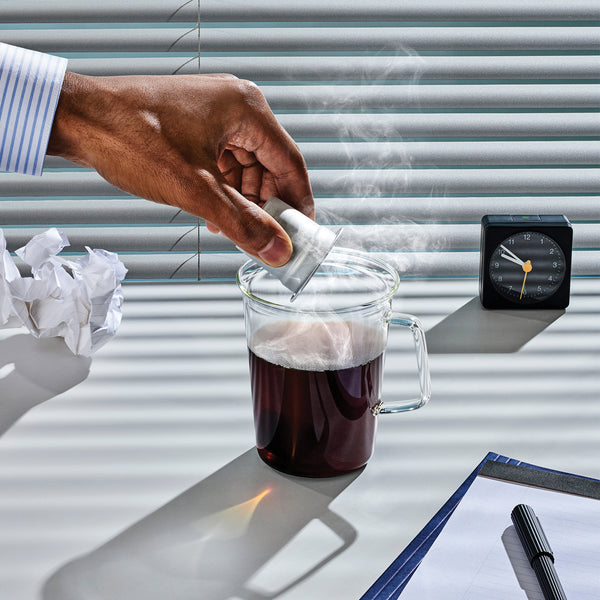

Make any café drink in seconds

Without the machine—or the café line. Just melt to enjoy. Hot, iced, or latte.

Thousands of 5 Star Reviews

All I can say is wow

The coffee Cometeer experience is incredible. It’s having a high end cup of coffee from a boutique coffee shop at my fingertips

Michael F.

Soooo good

It is hard to believe this is not coming from a live barista instead of my freezer.

Marisa C.

I love it

Not only is this coffee super convenient to brew right in my office, it is so flavorful and so delicious!

Joanna D.

Excellent flavor and body

Excellent flavor and body. Perfect when rushing in the morning.

Lynn B.

Delicious

Spectacularly delicious and so so easy.

Alice K.

Best cups of coffee

Every cup of Cometeer coffee I have is literally one of the best cups of coffee I've ever had.

Austin S.

Always a pleasant treat

Always a pleasant treat to arrive home on delivery day and see that box by the door. Never worry about product going bad within its confines. Especially appreciate total recyclability of product. Always on time.

Robert C.

Easy!

Easy! Perfect hot cup every time.

Paula R.

Best I have tasted

My overall experience drinking the capsules is excellent. The coffee is the best I have tasted. I set aside time every day to enjoy a cup and relax.

Susan D.

Love

Love your coffee and love customer service.

Lori H.

Experience

Enjoyed the coffee and experience. Had tastings with the family.

Binnur A.

High Quality

Such a high quality product. Love it.

Sean F.

Sweet Frozen Capsule of Goodness

This particular coffee captures the essence of a fine espresso without any of the faffing about with gram scales and grinders. Just a perfect coffee every time.

Sandra M.

Exclusive

The ONLY coffee I’ll drink now

Elizabeth W.

Delicious!

That "coffee shop" taste, in my own home!

Joshua K.

Best Inventions 2022 time

Best New Product Award specialty coffee association

Best Coffee Subscription Product (#1) USA Today

Nothing short of transcendent.

The different varieties of drinks you can make are honestly incredible.

Easiest way to enjoy a great cup of coffee.

Unrivaled flavor, sustainably

-

fully recyclable

Our first-of-its-kind aluminum capsule is completely recyclable—no need to rinse out grounds.

-

less food waste

No more waste from stale beans, poor brewing, or pouring out leftover cold coffee pots.

-

100% composted grounds

We send all the spent grounds from our coffee to a local composting company.

By coffee people, for coffee people

Seth Rogen

[Cometeer capsules] are incredible. I couldn't believe how much flavor they had, how simple they were to make, and how fast and convenient it was, honestly. And it was just something that we started drinking all the time.

Co-Founder of Houseplant

James Hoffmann

What made me so excited about Cometeer was that finally great coffee had no barriers of equipment, or skills. Drinking some of the very best coffee in the world is now incredibly easy.

World Barista Champion

Helen Russell

We knew that Cometeer was doing something exciting and innovative to help people enjoy quality specialty coffee when and how they like it - making coffee more approachable and accessible.

Co-Founder and Executive Chair of Equator Coffees

David Chang

I’ve always loved pour over coffee but didn’t have the time or expertise needed to make it correctly. Cometeer makes great coffee more accessible for me.

Michelin Star Chef

George Howell

Cometeer will do for coffee what the bottle did for wine.

Coffee roaster